Mission

MetalMorphosis Consortium aims to offer to the European Manufacturing industry integrated services on product development and its industrialization on hybrid metal-composite products, taking advantages of the complementary knowledge of the Consortium partners.

Namely, MetalMorphosis consortium takes advantage of its unique knowledge on Electromagnetic joining processes as results of MetalMorphosis project.

Also the consortium aims to disseminate the application of the EMJ technologies and seek for further developments on these technologies.

History

The Consortium was born in 2013 in order to develop the MetalMorphosis project, under the 7th Framework Programme.

The project was 30 month long and focused the optimization of electromagnetic joining of metal-composite parts, namely tubular and flat parts.

During its development partners had perform more than 830 trials in order to characterize joints over 11 joint concepts for tubular parts and 4 joining concepts for flat parts.

Also, several composite configurations were tested in order to achieve high strength and quality joints between metal and composites.

The work performed in the framework of the project allowed to achieve a range of optimized joining configurations depending of the objective of its application, namely in what regards to the required joining strength. Also the consortium developed the ability to simulate with high accuracy both the characteristics of the hybrid part and the specification of the EMJ process.

The knowledge developed within the project was demonstrated in three case studies of product application for the automotive industry, namely hybrid shock absorber, brake pedal and bumper.

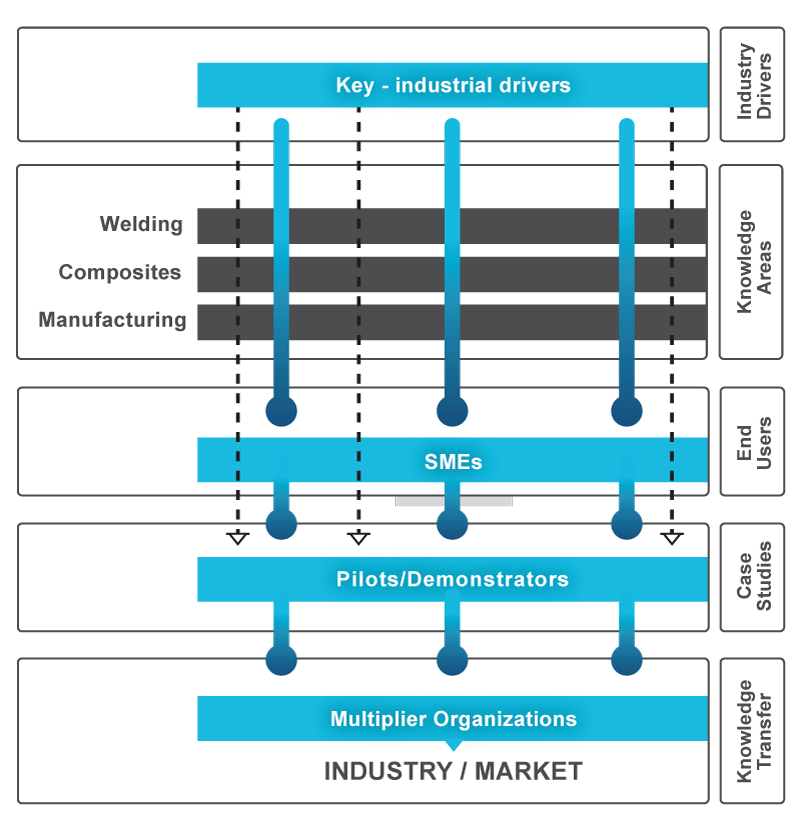

Consortium

MetalMorphosis consortium comprises 4 SMEs, 4 Research organisations and 1 multi-national industrial from 6 different European countries (Spain, Deutschland, Belgium, Portugal, Italy and Slovenia).

The consortium is led by CENTIMFE - Technological Center for the Mouldmaking, Special Tooling and Plastic Industries based in Portugal. Each partner has a unique knowledge and experience, which results in a defined role for the project, making it more accurate and coherent.

Portugal…

Belgium…

Spain…

Spain…

Germany…

Slovenia…

Italy…

Belgium…

Portugal…

Keep in touch with us

Optimization of Joining Processes for New Automotive Metal-Composite Hybrid Parts

Collaborative Project - FP7-2013-NMP-ICT-FOF(RTD)

GA nr.609039